Gasket Manufacturing Company

Welcome to Gasket Engineering! Our gasket company manufactures custom gaskets for numerous industries ranging from aerospace to medical. We can convert and bind virtually any raw material into the exact shape, dimensions, and thickness required for your manufacturing needs.

Family Owned and Operated for Over 60 Years

Built on a heritage of die-cutting expertise, expansive state-of-the art facilities and a top-level drive for continuous technology adoption, Gasket Engineering maintains in-house expertise in converting a multitude of materials in facilities that house a large selection of machinery across many industries. Our drive for superior customer service and performance ensures that we keep up to date on the latest innovations to serve our customers.

Latest Posts

https://www.gasketeng.com/wp-content/uploads/2013/04/Registered-to-ISO-9001_black_RGB.jpg

347

222

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-10-28 04:14:162017-10-28 19:59:40Gasket Engineering is ISO 9001:2015 Certified!

https://www.gasketeng.com/wp-content/uploads/2013/04/Registered-to-ISO-9001_black_RGB.jpg

347

222

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-10-28 04:14:162017-10-28 19:59:40Gasket Engineering is ISO 9001:2015 Certified! https://www.gasketeng.com/wp-content/uploads/2017/06/as-seen-in-CMM.jpg

1040

1800

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-05-25 18:41:432017-06-13 18:47:31We’re in the press (again)!

https://www.gasketeng.com/wp-content/uploads/2017/06/as-seen-in-CMM.jpg

1040

1800

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-05-25 18:41:432017-06-13 18:47:31We’re in the press (again)! https://www.gasketeng.com/wp-content/uploads/2017/06/IMG_1080.jpg

480

640

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

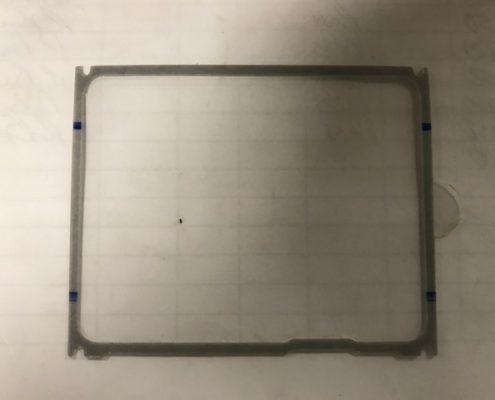

atiadmin2017-05-11 19:26:282017-06-13 19:51:10Got Thin Wall Widths? Laser Cutting To The Rescue!

https://www.gasketeng.com/wp-content/uploads/2017/06/IMG_1080.jpg

480

640

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-05-11 19:26:282017-06-13 19:51:10Got Thin Wall Widths? Laser Cutting To The Rescue! https://www.gasketeng.com/wp-content/uploads/2017/05/biometrics-154660_1280.png

810

1280

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-04-25 21:09:032017-05-02 22:21:11Closed-Cell Sponge Gaskets For a Security System

https://www.gasketeng.com/wp-content/uploads/2017/05/biometrics-154660_1280.png

810

1280

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-04-25 21:09:032017-05-02 22:21:11Closed-Cell Sponge Gaskets For a Security System https://www.gasketeng.com/wp-content/uploads/2017/05/Calender-coating.jpg

360

409

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

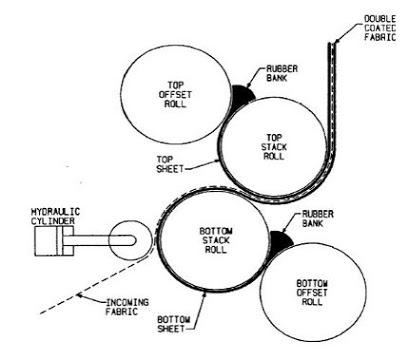

atiadmin2017-04-13 23:14:572017-05-03 16:05:16Engineered Coated Fabric Or Diaphragm Material

https://www.gasketeng.com/wp-content/uploads/2017/05/Calender-coating.jpg

360

409

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-04-13 23:14:572017-05-03 16:05:16Engineered Coated Fabric Or Diaphragm Material https://www.gasketeng.com/wp-content/uploads/2017/03/You-Gotta-Be-Here.jpg

923

912

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-03-27 07:27:072017-03-31 07:29:31Innovation and the Founding of the Gasket Fabricators Association

https://www.gasketeng.com/wp-content/uploads/2017/03/You-Gotta-Be-Here.jpg

923

912

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-03-27 07:27:072017-03-31 07:29:31Innovation and the Founding of the Gasket Fabricators Association

New Manufacturer’s Rep Looks For Diversified Custom Gasket Manufacturer

https://www.gasketeng.com/wp-content/uploads/2017/02/miner-1903636_1920.jpg

1280

1920

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-02-27 22:32:112017-02-28 19:22:52PTFE Microfiltration Membrane Materials Help Save Lives

https://www.gasketeng.com/wp-content/uploads/2017/02/miner-1903636_1920.jpg

1280

1920

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-02-27 22:32:112017-02-28 19:22:52PTFE Microfiltration Membrane Materials Help Save Lives https://www.gasketeng.com/wp-content/uploads/2017/01/Master-Fabricators-Trelleborg.jpg

711

1292

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-01-26 18:47:082017-03-09 15:34:15Gasket Engineering Chosen As Trelleborg Master Fabricator

https://www.gasketeng.com/wp-content/uploads/2017/01/Master-Fabricators-Trelleborg.jpg

711

1292

atiadmin

https://www.gasketeng.com/wp-content/uploads/2015/10/Gasket-HeaderLogo1-300x91.png

atiadmin2017-01-26 18:47:082017-03-09 15:34:15Gasket Engineering Chosen As Trelleborg Master FabricatorCustom Gasket Company

Experience

With over 60 years of experience as a custom gasket manufacturing company, we have mastered the art and precision of producing custom gaskets across a wide range of industries and applications. Customers utilize our knowledge to help them solve their most challenging engineering issues. We provide guidance on the material and process that results in the most precise gasket for each specific project. The breadth of knowledge and customer service we provide sets us apart from other gasket companies.

Materials

From standard gasket materials (such as compressed sheet) to highly specialized materials (such as thermal transferring material), our digital die cutting equipment can provide precise edging to exact size and thickness specifications. We use only the highest quality materials from the world’s most respected suppliers such as Composite One, 3M, Rogers, BRP and more.

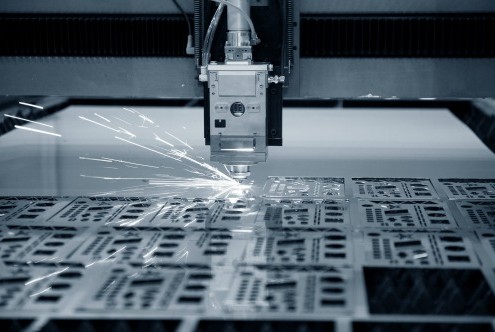

State-of-the-art Equipment and Facility

We invite you to visit our centrally-located gasket company in Kansas City, Missouri. With over 140,000 square feet of gasket manufacturing space which houses four different types of die-cutting equipment from rotary to laser, we have the equipment and space to fulfill any gasket request. We are ISO-9001 certified and meet all federal and state safety and environmental regulations.

Capacity

Need 10 million custom gasket parts? No problem! No job is too small or too big for this custom gasket manufacturer!

Customer Service

We pride ourselves on helping our customers get the highest quality parts built to their exact specifications on time. Custom gasket manufacturing requires the full spectrum of factors: the right materials, cut by the best equipment, run by trained professionals, and managed by a team that is supervising the project from start to finish. This is the Gasket Engineering difference!

Testimonials

Less work, more profits. That’s why we work with Gasket Engineering.

While many other converters can’t generally handle layering multiple materials and multiple geometrics into a single product, Gasket Engineering just told me ‘No problem’ and went about figuring out how to accomplish what we needed. They are out-of-the-box thinkers who have the experience converting materials in non-typical ways.

Gasket Engineering’s innovative thinking and can-do approach has allowed us to improve our customer’s experience when installing our product on their equipment.

To access the machine-readable files created and published by UnitedHealthcare, please click here.

Latest News

Gasket Engineering is ISO 9001:2015 Certified!October 28, 2017 - 4:14 am

Gasket Engineering is ISO 9001:2015 Certified!October 28, 2017 - 4:14 am We’re in the press (again)!May 25, 2017 - 6:41 pm

We’re in the press (again)!May 25, 2017 - 6:41 pm Got Thin Wall Widths? Laser Cutting To The Rescue!May 11, 2017 - 7:26 pm

Got Thin Wall Widths? Laser Cutting To The Rescue!May 11, 2017 - 7:26 pm Engineered Coated Fabric Or Diaphragm MaterialApril 13, 2017 - 11:14 pm

Engineered Coated Fabric Or Diaphragm MaterialApril 13, 2017 - 11:14 pm Innovation and the Founding of the Gasket Fabricators AssociationMarch 27, 2017 - 7:27 am

Innovation and the Founding of the Gasket Fabricators AssociationMarch 27, 2017 - 7:27 am

Phone: 816.363.8333

Fax: 816.363.3558

Email: GECsales@gasketeng.com

4500 East 75th Terrace

Kansas City, MO 64132