Need a Release Liner Manufacturer? We’ve Got You Covered!

A release liner is a release liner is a release liner…they are all the same, right? Wrong!

Whether you are using a simple, straightforward production process or engineering something for a very intricate, complicated methodology, choosing the right release liner and the right release liner manufacturer can make a big difference in run rates, waste, and overall profitability. Getting a professional analysis done by a team of experts from a release liner manufacturer that is experienced in figuring out exactly what is needed can make a BIG difference.

Gasket Engineering has helped companies replicate processes when they want to bring foreign-made part production back to the United States and streamline those manufacturing processes once they come back. When it comes to picking the right release liner, there are several important factors to consider: material choice, release tension, adhesive type and application process.

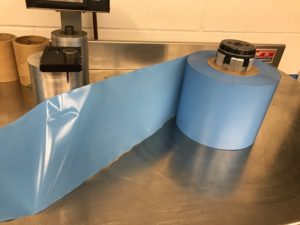

Release Liner Material Choices

A release liner can come in a variety of substrates including:

Release Liner Properties

The ease of release is another factor and is determined by the silicone release liner coating which can be easy, medium, or tight depending on the coat weight. The less silicone on the part, the tighter the release will be and vice versa. The substrate in the application also has a lot to do with the ease of release.

Will it be a multi-line layer or single line layer? When customers need a one-sided silicone release liner, an easy release liner would usually be used. It’s a little trickier when you have a double release adhesive application as one side needs to come off easier than the other side. Once the customer has communicated how the product is going to be used, a determination can be made as to whether the second side will need easy, medium or tight release properties.

If needed, Gasket Engineering will send samples set at different coat weights so that the customer can test them out in their application and provide feedback on which silicone release liner worked best. This allows time to make the necessary adjustments to the release properties before going into full production.

Adhesives

Just as it is critical to know what materials you are using, it is also important to understand what type of adhesive is being used. For example, VHB tape will react very differently than other adhesives and would require a different type of liner.

Application Process

Of course, the final choice of material and release substrates will ultimately be determined by the application and manufacturing process being used. Do you need the product to be in rolls or on sheets? Is it hand-applied or done in line? This is where time and experience can be the most important factor of all. If the release properties are not correct, the part may come off too easily (and result in a mess of extra parts scattered on the production equipment or lying waste on the manufacturing floor) or conversely, not come off onto the part, resulting in inferior-quality company parts. With over 60 years of experience as a release liner manufacturer, Gasket Engineering knows what it takes to provide their customers with perfect parts every time.